Related Products

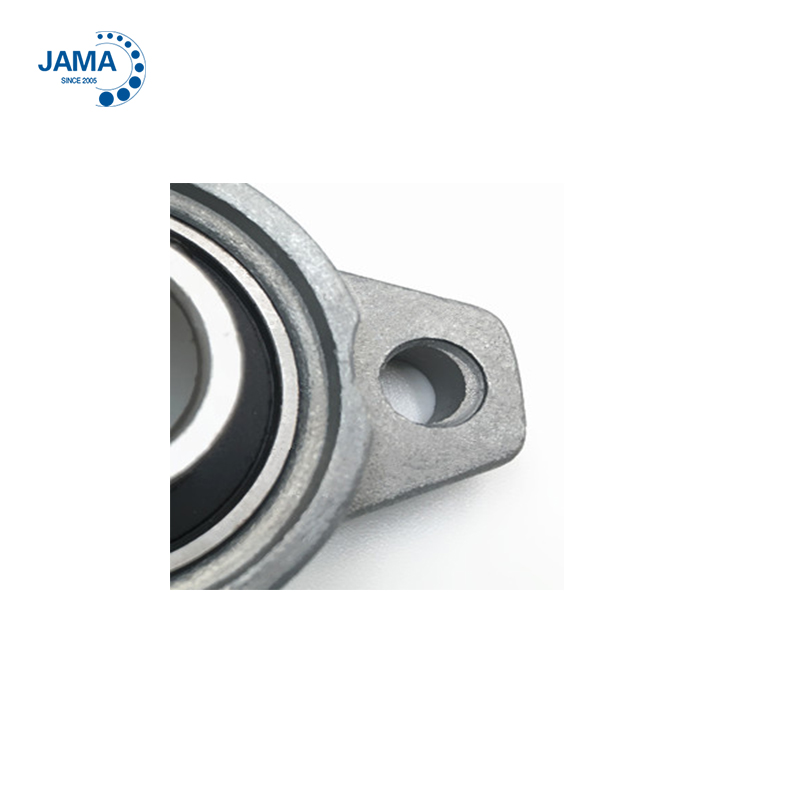

| Type: | Zinc alloy bearing units |

|---|---|

| Brand Name: | JAMA |

| Model Number: | UP000,UFL000,KP000,KFL000 |

| Material: | Housing: zinc alloy; insert ball bearing: chrome steel GCr15 |

| Tolerance | J7, H7, H8, H9 |

Copyright © 2019Xiamen JAMABearing Co., Ltd. | All Rights Reserved.

Hello, please leave your name and email here before chat online so that we won't miss your message and contact you smoothly.