Related Products

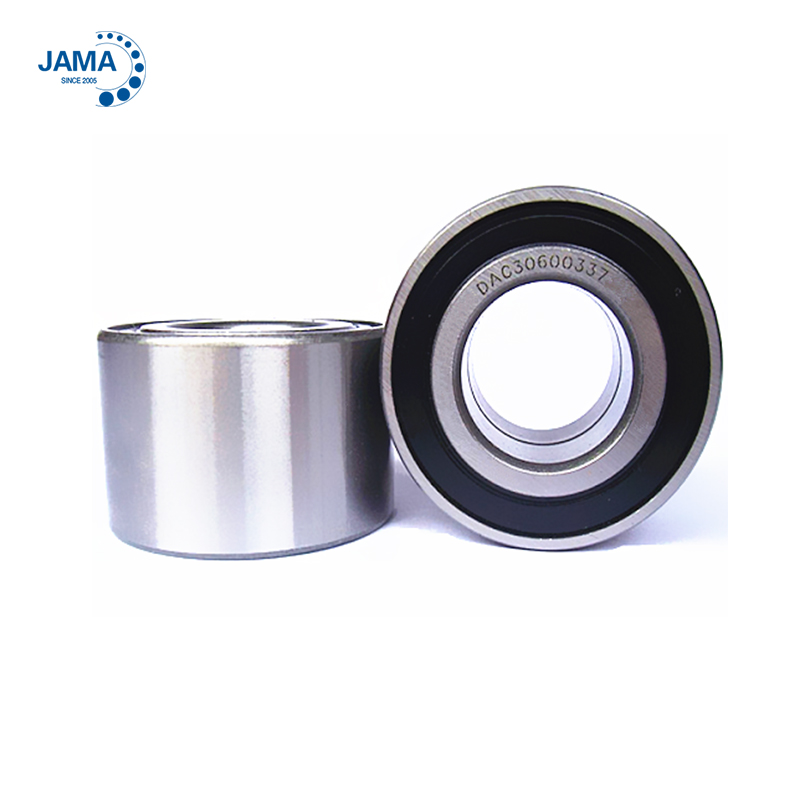

| Type: | Wheel hub bearing |

|---|---|

| Brand Name: | JAMA |

| Model Number: | DACseries,DACFseries,DAC2Fseries,THU1series,THU2series, TBseries |

| Material: | Chrome steel |

Copyright © 2019Xiamen JAMABearing Co., Ltd. | All Rights Reserved.

Hello, please leave your name and email here before chat online so that we won't miss your message and contact you smoothly.