Contact Sales at JAMA

What about the production flow for ball & roller bearings in JAMA?

2020-08-12

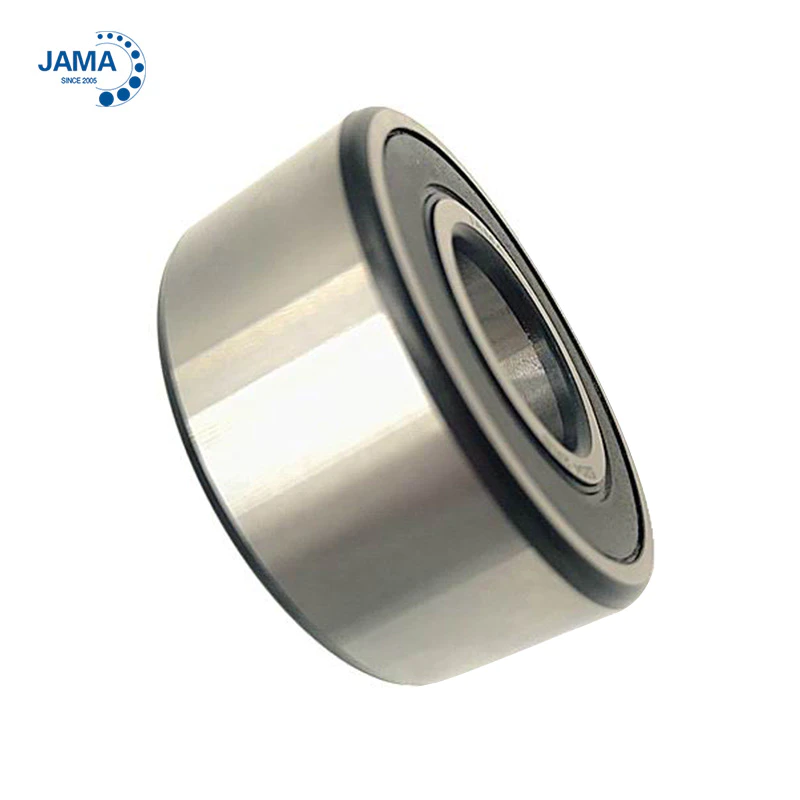

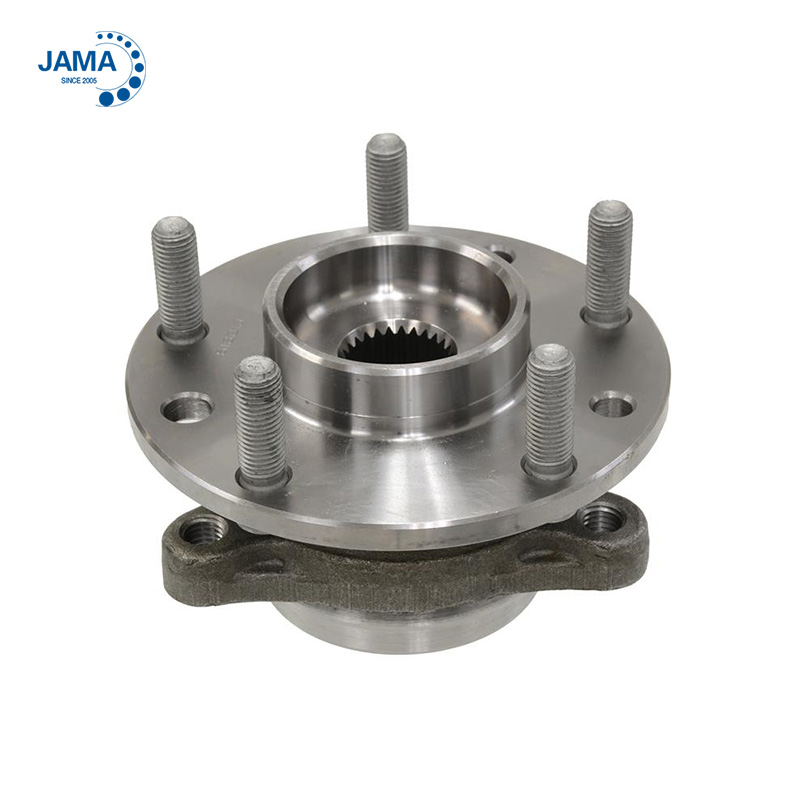

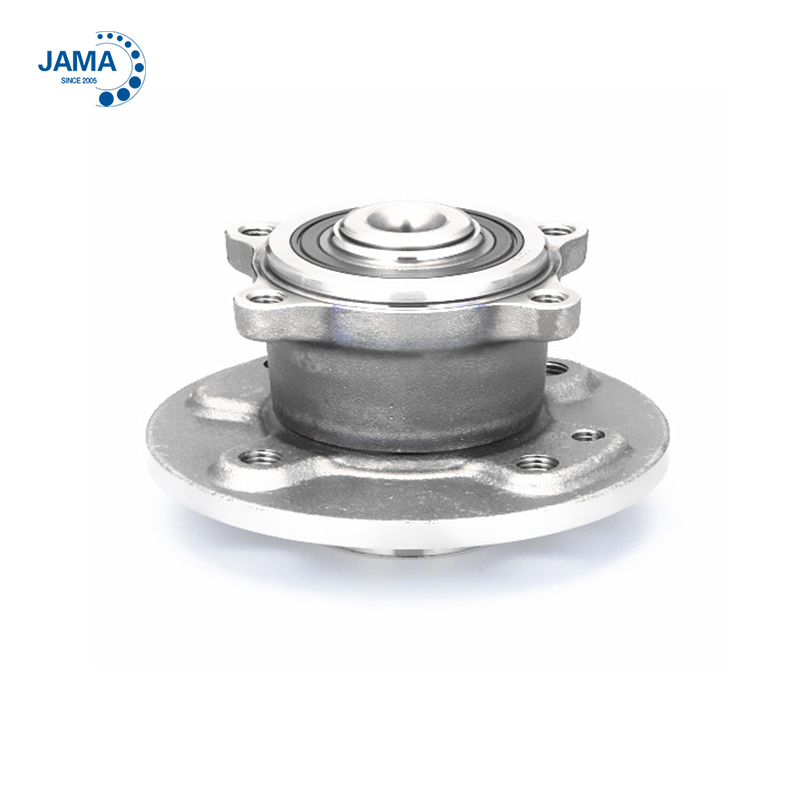

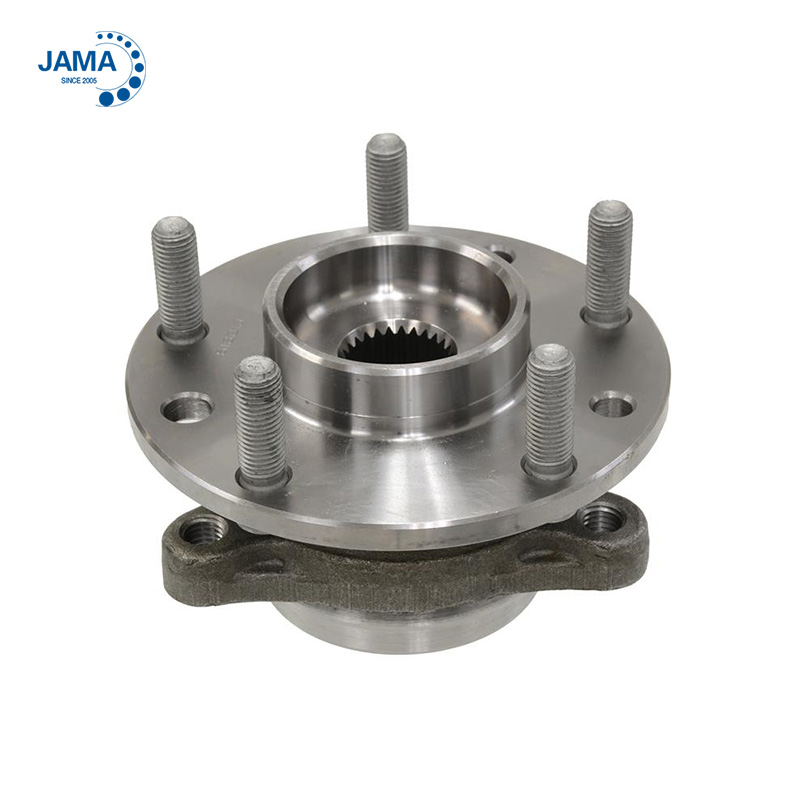

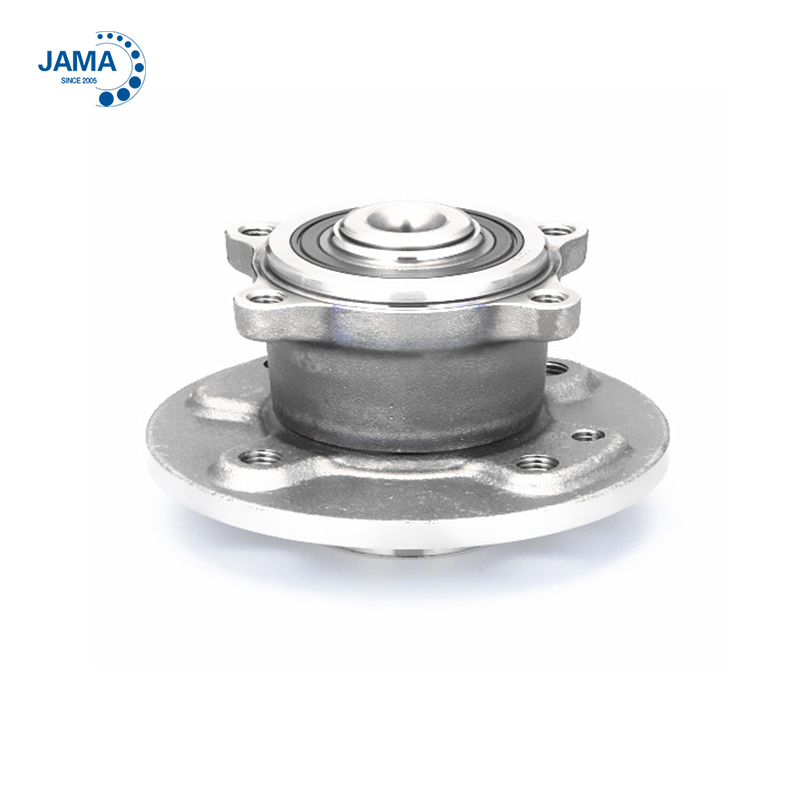

The production flow of ball & roller bearings in Xiamen JAMA Bearing Co., Ltdis regarded as mature and highly cost-efficient. After years of development, we have formed a unique and feasible production flow to facilitate the manufacturing of the product. It starts with quick material sourcing and inspection. Machines are adopted to reduce labour costs and improve efficiency. Before the finished product is shipped out, relevant checkings are conducted to ensure a high pass rate. The product appearance and functions will be measured according to international standards.

JAMA is a passionate manufacturer specializing in the production of pillow block housing with high-quality standards. We have accumulated many years of production experience. According to the material, JAMA's products are divided into several categories, and bearing units is one of them. Different water purification technique has adopted by JAMAoil seal ring, such as physical and chemical filtration. These two purification techniques can greatly enhance the purifying effect. The product has a unique heat sink that provides the path for heat to travel from the light source to outside elements, which effectively improve the management of heat.

We work hard to protect and preserve environmental integrity. We incorporate many sustainability plans into each of our production processes, such as reducing waste discharge, save water and electricity, and make full use of resources.

JAMA is a passionate manufacturer specializing in the production of pillow block housing with high-quality standards. We have accumulated many years of production experience. According to the material, JAMA's products are divided into several categories, and bearing units is one of them. Different water purification technique has adopted by JAMAoil seal ring, such as physical and chemical filtration. These two purification techniques can greatly enhance the purifying effect. The product has a unique heat sink that provides the path for heat to travel from the light source to outside elements, which effectively improve the management of heat.

We work hard to protect and preserve environmental integrity. We incorporate many sustainability plans into each of our production processes, such as reducing waste discharge, save water and electricity, and make full use of resources.

Custom message